Federal-Mogul knows safety

Management support and employee buy-in resulted in three Federal-Mogul manfuacturing facilities recently achieving 1 million hours without a lost-time accident.

By Lisa B. Weber

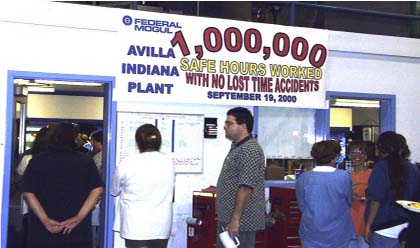

Avilla, IN, facility

Frankfort, IN facility

Orangeburg, SC, facility

Federal-Mogul has something to be proud of. Three of the company's manufacturing facilities -- in Avilla and Frankfort, IN, and Orangeburg, SC -- have reached the safety milestone of 1 million hours worked without a lost-time accident. Management's support of safety programs and policies, employee buy-in for the safety programs, and tailoring safety programs to the needs of each facility were instrumental in achieving such outstanding safety results.

"The achievement of these three teams reflects Federal-Mogul's serious approach and dedication to safety," said Robert S. (Steve) Miller, chairman and CEO. "We are very proud of the significant milestones achieved by our employees."

The safety excellence that these facilities exhibit reflects the high degree of employee involvement in safety awareness programs, training, safety committees and safety communication, added Miller.

The fact that the company places tremendous value on the efforts of its employees is apparent in its purpose statement, which has three elements, the first of which states that the "talented and dedicated people of Federal-Mogul are responsible for our success." The second element says "it's their relentless focus on the customer, serving our customers, that describes our reason for our existence." Finally, the company acknowledges "manufacturing mastery, is what distinguishes Federal-Mogul as our customers' supplier of choice."

As core values, Federal-Mogul lists:

- We are a team first.

- We respect, trust, and help each other.

- We act with integrity.

- We are driven toward mastery in all we do.

- We celebrate our success.

"It truly takes a team effort to reach a milestone of this magnitude and this achievement is a prime example of our employee's teamwork and commitment to a strong safety program," said Brian Banwart, plant manager at the Avilla facility.

Enhancements to Avilla's safety program over the past several years include: implementation of CD-ROM training modules for safety topics; a safety incentive program; a new reporting form for employees to submit safety concerns; development of a committee for guarding improvements; implementation of a "no jewelry" policy in manufacturing operations; and an active safety committee.

"While improvements to our safety program have been a significant part of this success, the congratulations truly belongs to our employees," said Kurt Meyer, facilities manager. "It is their hard work and support of the safety programs that leads us towards continuous improvement."

"The recognition for this accomplishment truly belongs to the employees who have made safety a priority in their job every day. It is their focus on working safely and reporting safety concerns that has made the difference," reports Scott Bruick, human resource manager.

Avilla manufacturers automotive lighting sockets, connectors, backplates and switches for automotive original equipment, and aftermarket applications. The plant also manufactures non-automotive pump components and thermostat housings.

Back to top

Frankfort, IN facility

In Frankfort, IN, A plant-wide lunch was held to celebrate the facility's achievement. Al Houser, plant manager, indicated that, "This was the first time in several years that the plant has reached this milestone, and we will continue to work toward achievement of the Federal-Mogul Gold Safety Award at the end of this year." Houser said that plant management is "very proud" of the effort employees made to accomplish this milestone. "We received the Corporation's Bronze Significant Improvement Safety Award in 1998 and the Silver award in 1999. We are well on our way to receiving the Gold award this year," Houser added.

The Frankfort plant has a number of ongoing safety initiatives in place to focus on continual safety improvement. They are employee safety recognition and reward programs, training, frequent safety newsletters and orientation, visible safety posters and a central safety information board.

"Our staff has completed the DuPont safety training and supervisor training begun in September," said Houser. "We believe that this training will help take us to the next level, and we are developing the culture that is beginning to subscribe to the notion that we can reduce and eliminate accidents. We believe we can do it with a focused effort of employee involvement and continuous improvement."

Frankfort manufactures radial lip oil seals and transmission pistons (Unipiston seals) used in a wide range of vehicle applications and employs approximately 850. Established in 1964, the plant is part of the global Federal-Mogul Sealing Systems group, which is a leading supplier of complete systems-based sealing solutions for automotive, heavy-duty and industrial applications.

Back to top

Orangeburg, SC, facility

"This achievement is the result of a great team effort," said Orangeburg's Human Resources Manager Gayle Carter. "Our employees truly understand that their health and safety are a priority."

those at Orangeburg, reached the million hour milestone.

The safety excellence this facility has achieved was rewarded last year when the Orangeburg plant won the Federal-Mogul Health and Safety Significant Improvement Bronze Award for 1999. This award is given to a facility that improves its safety score compared to the prior year's score.

In addition to these achievements, Orangeburg has recently introduced 60-second safety vignettes during each shift's team meeting to obtain a focus on safety when starting the day.

"Our safety philosophy is summed up with the phrase 'Keeping Yourself Safe'," said Jeff Hawley, plant manager, Orangeburg, South Carolina. "We focus on improving safety by rigorous training, education, auditing and awareness."

Orangeburg manufacturers brake pads for automotive original equipment customers and employs approximately 300.

Headquartered in Southfield, MI, Federal-Mogul is an automotive parts manufacturer providing innovative solutions and systems to global customers in the automotive, small engine, heavy-duty and industrial markets. The company was founded in 1899.